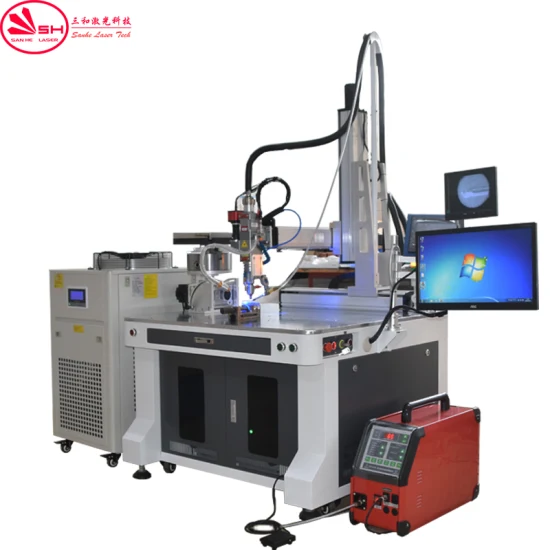

3D 1kw 2kw Robot Laser Welding Machine in Automotive Shipbuilding Industry

Handheld Fiber Laser Welding Machine1.PRODUCT DESCRIPTION : The laser welding machine employs high-octane laser pulse to

Basic Info.

| Model NO. | HY-WA02 |

| Power Requirement | 220V/50Hz&60Hz 3800V/50Hz&60Hz |

| Power Regulation | 10-100% |

| Wire Feeding System | Option ( 1.0mm-2.0mm) |

| Cooling Method | Water Chiller |

| Product Name | Handheld Laser Welding Machine |

| Overall Power Comsumption | <=2kw, 3kw,4 Kw |

| Application Material | Stainless Steel, Carbon Steel Aluminum |

| Power Instability | <3% |

| Laser Frenquency | 50-5000Hz |

| Laser Wavelength | 1024nm |

| Weading Head | Wobble Laser Welding Head |

| Welding Head | Wobble or Static |

| Welding Depth | 2.0-4.0mm |

| Max. Power | 1000W 1500W 2000W |

| Laser Source | Raycus/ Jpt/ Ipg/Reci |

| Transport Package | Plywood Box |

| Specification | 1100*550*950 |

| Trademark | HAIYI Laser |

| Origin | Jiangsu/China |

| HS Code | 8515809090 |

| Production Capacity | 1000sets/Year |

Product Description

Handheld Fiber Laser Welding Machine1.PRODUCT DESCRIPTION :The laser welding machine employs high-octane laser pulse to heat one particular area of tiny areas on a work material. The powerful energy of laser radiation diffuses into materials' internal parts through heat conduction, and then the melting material will form a specific molten bath to facilitate the laser welding.

2. APPLICATION :

Laser Welding Machine is widely used in mobile phone battery shell, houshold appliances,electronic components, mobile communication, hardware products, automotible accessories, glasses, kitcen industry , advertisement, stainless aluminum windows and doors, medical equipment, thermal cups and etc. other industries.

3.SPECIFICATION :

| Model | HY-WF1000W/HY-WF1500W/HY-WF2000W |

| Laser Power | 1000W/1500W/2000W |

| Laser Wavelength | 1064nm |

| Laser Frenquency | 50-5000HZ |

| Power Adjustment | 10-100% |

| Welding Depth | 0.2-3.5mm |

| Cooling Method | Water Chiller |

| Spot Size | 1.2-3.0mm (option) |

| Wobble Head | Option |

| Power Instability | <3% |

| Power requirement | 220V/ 50&60HZ; 380V/50&60HZ (above 1500W) |

| Overall Power Consumption | <2KW, 3KW |

| Over Size(L*W*H) | 1100*550*950mm |

| feeding wire's dimension | 1.0-4.0mm(SS, Aluminum, Brass) |

| Gross Weight (Net Weight) | 270KG/200KG |

A. The machine is easy to handle and don't need the professional welder.B. With 8-15m fiber wire, Can weld long-distance and large-area parts.C. High quality and very stable: With a long lifespan to 100000 hours and free of maintance.

D. High efficiency: more than 5 times of the TIG welding with low energy consumption.

E. Various welding proceses: jam welding, seal welding, spot welding, stitch welding and overlap welding .F:Inappreciable heat-affected zone, little deformation good-looking smoothly welding seam.G. Little remedial work after welding, high-quality of welding line, precise control of positioning accuracy, small spot focus and automated weldingH: Low cost, no consumables, energy saving and enviroment protection.I: Can support the different welding wires for stainless steel, Aluminum and Copper

5. OUR SERVICE :

1. 1 year Guarantee for the whole machine.

2. 12 months Guarantee and free spare parts supply during this period.

3. 24 hours on line service

4. 3-7 days lead time

5. We will provide the Instruction Book, Operational manual and Training Video

6. Provide technical support for the whole lifetime on line

7. TT/Ali Trade Assurance payment

8. Shipping By air, DHL, Sea.

6.ABOUT US :

7.FAQ:

Q1. How to select the suitable machine?

Tell us your material, detail requirements by words, pictures or video.

We will recommend you the suitable model with the reasonable price.

Q2. How about the lead time?

For the standard machine, the delivery time is 3-7 days after the payment.

For the non-standard machine, the delivery time is 7-15 days after the payment.

Q3. How to install and use it?

We have the instruction Book, Operational manual and Training Video inside the machine.

We also can provide the training on line by free.

Q4. How to do it if we meet the issue during the operation?

You can send the wrong information to us by mail, we can help us solve it by mail.

phone, or video communication.

Q5. If we want to learn how to operate the machine, Can you provide it?

Yes, we can. We can provide the on line training by video. We also provide free training

course in our company.

Q6. Do you provide the onsite service if we needed?

Yes. We can provide the onsite service if you needed. But need the customer pay for the transport, hotel, food and 60USD/day.

Send to us