Uph 8500+ Dots Precision 0.2mm

JD-BBW Double Station Automatic Positioning Laser Solder Ball Jetting Solerding Precision Welding Machine for IC Wafer H

Basic Info.

| Model NO. | JD-BBW |

| Origin | Hubei, China |

| Production Capacity | 1000 Sets/Month |

Product Description

JD-BBW Double Station Automatic Positioning Laser Solder Ball Jetting Solerding Precision Welding Machine for IC Wafer HD Camera Module Sensor BGA ReballingProduct introductionThe working principle of the laser solder ball welding machine is that the solder balls fall into the guide channel and finally stop at the bottom of the nozzle after passing through the precision ball separation device. After being melted by laser heating, it is jetted from a special nozzle and directly covers the pad without additional flux or other tools. Solder ball spray welding is adopted, which has high welding precision and can realize precise welding for the soldering has a temperature requirements or soft board connection welding area. During the whole process, the solder joints are not in contact with the welding body, which solves the electrostatic threat caused by contact during the welding process. The welding yield rate is 99%.

Range of applications

Products are widely used in the microelectronics industry: such as HD camera modules, mobile phone digital camera soft board connection point welding, precision sound control devices, data line welding point assembly welding, sensor welding. Electronics manufacturing industry: aerospace high-precision electronic product welding. Other industries: Welding of wafers, optoelectronic products, MEMS, sensor production, BGA, HDD (HGA, HSA) and other high-precision components, and high-precision electronics.

Advantages of laser tin ball welding

Laser tin ball welding process:

-Applied to high precision micro tin welding

-Suitable for gold plating, silver, tin, copper welding surface

Advantages of tin ball welding:

-No rosin residue, free from cleaning

-The tin ball is melted by laser in the nozzle. The laser does not act directly on the solder joint, reducing the probability of scalding the peripheral devices

-Efficient fast

-The size of the tin ball is fixed to ensure the consistency of the solder joint

-Non - contact welding, small thermal effect on welding joints, no splash pollution

Specification of tin ball:

-Accuracy: + / - 3 um

-Tin ball (optional): 100um-750um

DY-BBW Outline Specifications

| Machine Model | DY-BBW |

| Outline Size | 950mm X 850mm X 1650mm |

| Rated Voltage | AC220V |

| Maximum Current | 25A |

| Compressed Air | 0.7MPa |

| Nitrogen | 0.5MPa |

| Vacuum | -80Kpa |

| Laser Power | 150W(Optional 200W) |

| Working area | 300mm X 300mm(single position) |

1. The equipment can be fed in and out of the track, and the X, Y and Z axes are respectively used for visual positioning and ball jet welding;

2. CCD is used to take photos, and the ontology feature recognition function automatically compensates the positioning deviation value (+/-3um);

3. From feeding to welding and then to discharge fully automatic completion, reduce manpower to effectively ensure the consistency of welding

4. Maximum production capacity UPH: > 8500 dots

Product Features

It is applied to the products that need small, three-dimensional, non-contact welding

Equipped with visual positioning system

Welding mode: high efficiency laser welding, non-contact welding, eliminate static electricity, friction and other external forces;

Welding space: welding can be completed in a small space, three-dimensional welding;

Motion system: Imported servo motor, high precision parts, better precision, leading the industry.

Structure system: Adopt the whole marble gantry platform structure, the structure does not deform, and the precision stability is better in the long use of the equipment

Single point speed: >4 seconds; Yield rate :99% or above;

Laser supplier: imported/domestic

Joint: equipped with cleaning system, adjustable position of three axes, convenient and accurate, time and labor saving.

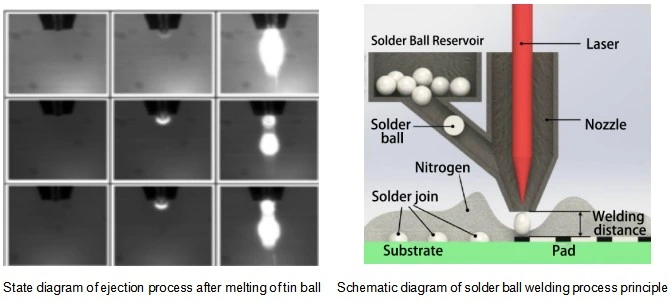

Principle of laser tin ball ejection

The tin ball is implanted into the nozzle individually. When the tin ball reaches the tip of the nozzle, laser is fired, and the laser melts the tin ball. The molten tin ball is sprayed to the solder pad by pressure nitrogen, and the welding is completed.

Laser tin ball injection characteristics

1. The size of the tin ball is fixed to ensure the consistency of the size of the welding point;

2. Non-contact jet welding;

3. High welding efficiency, generally can achieve 3dots/s (3 points per second) welding efficiency (the specific situation needs to be judged according to the distance between solder joints);

4. Laser melting tin ball, tin ball melted into tin liquid is sprayed to the solder pad, heat affected zone is small;

5. Realize the spray welding of the tin ball diameter of 0.2mm, 0.3mm, 0.4mm, 0.5mm, 0.6mm, 0.76mm and 0.9mm. The ejection head of 0.25, 0.45, 0.55, 0.65, 1.0, 0.2mm diameter tin ball can be customized.

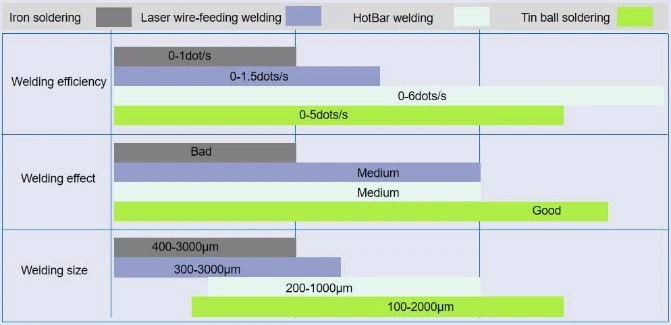

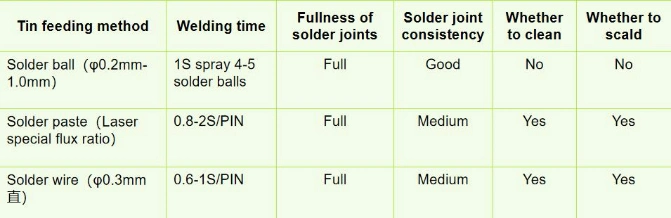

Comparison of laser spray solder ball welding and traditional welding

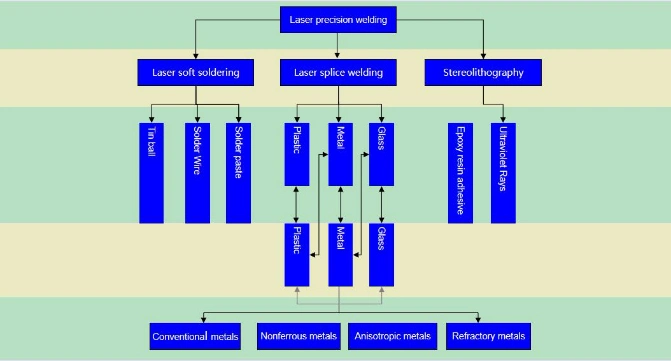

Laser spray solder ball welding and other laser precision welding comparison

Laser Precision Soldering

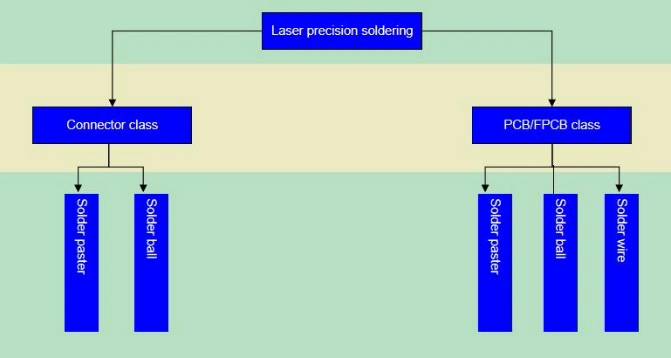

Comparison of various laser soldering effects

1. FPC flexible circuit board welding

2. flat motor

3. BGA ball graft repair

4. CCM, VCM camera module welding

5. precision sound control device welding

6. laminated circuit board welding

7. automotive electronic aluminum substrate

welding (particularly rapid cooling)

Conclusion: The diameter of the solder joint is less than 2mm, and the pad material is tin, copper, silver, nickel and other tin loving materials, which are suitable for solder pad bonding, tin is jetted on the pad, materials around the pad that are not resistant to high temperature and other processes. It is required that the temperature of the two pads to be welded should be equal, and there should be no significant difference (to ensure that the wettability of the two pads is equal at the same temperature).

Send to us